Scroll Compressor

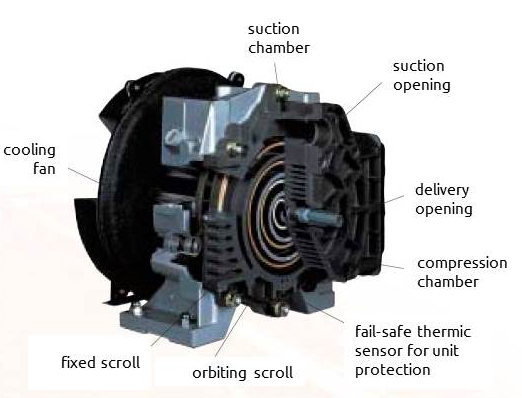

A scroll compressor (also called spiral compressor, scroll pump and scroll vacuum pump) is a device for compressing air or refrigerant. In rolling stocks, scroll compressor is used for HVAC and brake systems.

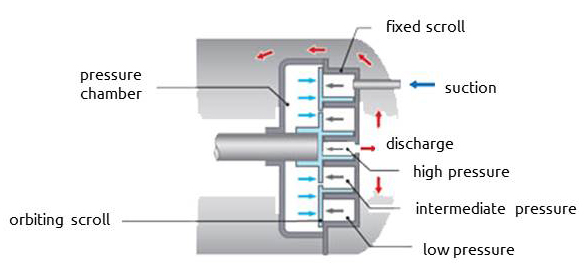

The orbiting scroll is coupled to the crankshaft and orbits, rather than rotates. The orbiting motion creates a series of gas pockets traveling between the two scrolls. On the outer portion of the scrolls, the pockets draw in gas, and then move into the center of the scroll, where the gas is discharged. As the gas moves into the increasingly smaller inner pockets, the temperature and pressure increase to the desired discharge pressure.

Advantages;

– Very quiet.

– It is very small

– Simple design, not so many parts

– Low maintenance (hardly any)

– Oil-free design

Disadvantages;

– Low capacity (flow, liters/minute or cfpm).

– Relatively expensive

– When the compressor-element fails, there’s a very big chance you just have to buy a whole new element.

– The compressed air gets very hot! Much hotter than compared to other types of compressors

Videos;

Sources; emersonclimate.com, air-compressor-guide.com, hitachi-ap.com