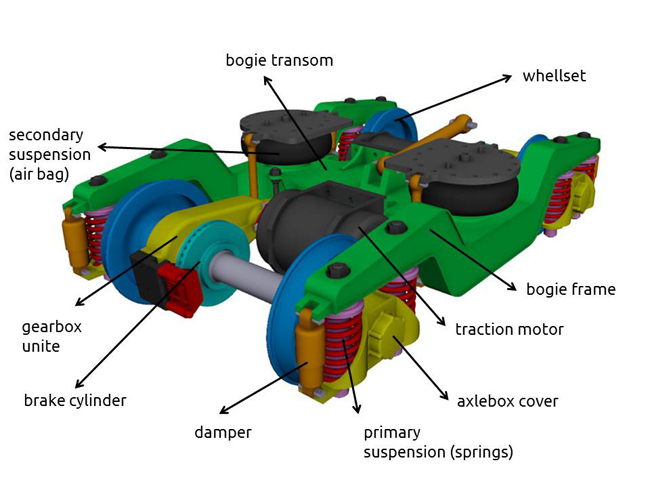

Bogie

In mechanics terms, a bogie is a frame work which carrying wheels attached to coaches. The bogie, or truck as it is called in the US, comes in many shapes and sizes but it is in its most developed form as the motor bogie of an electric or diesel locomotive or an EMU. Here it has to carry the motors, brakes and suspension systems all within a tight envelope. It is subjected to severe stresses and shocks and may have to run at over 300 km/h in a high speed application.

Bogie Frame

Can be of steel plate or cast steel. In this case, it is a modern design of welded steel box format where the structure is formed into hollow sections of the required shape.

Bogie Transom

Transverse structural member of bogie frame (usually two off) which also supports the carbody guidance parts and the traction motors.

Brake Cylinder

An air brake cylinder is provided for each wheel. A cylinder can operate tread or disc brakes. Some designs incorporate parking brakes as well. Some bogies have two brake cylinders per wheel for heavy duty braking requirements. Each wheel is provided with a brake disc on each side and a brake pad actuated by the brake cylinder. A pair of pads is hung from the bogie frame and activated by links attached to the piston in the brake cylinder. When air is admitted into the brake cylinder, the internal piston moves these links and causes the brake pads to press against the discs. A brake hanger support bracket carries the brake hangers, from which the pads are hung.

Primary Suspension Coil

A steel coil spring, two of which are fitted to each axlebox in this design. They carry the weight of the bogie frame and anything attached to it.

Motor Suspension Tube

Many motors are suspended between the transverse member of the bogie frame called the transom and the axle. This motor is called “nose suspended” because it is hung between the suspension tube and a single mounting on the bogie transom called the nose.

Gearbox

This contains the pinion and gearwheel which connects the drive from the armature to the axle.

Motor

Normally, each axle has its own motor. It drives the axle through the gearbox. Some designs, particularly on tramcars, use a motor to drive two axles

Neutral Section Switch Detector

In the UK, the overhead line is divided into sections with short neutral sections separating them. It is necessary to switch off the current on the train while the neutral section is crossed. A magnetic device mounted on the track marks the start and finish of the neutral section. The device is detected by a box mounted on the leading bogie of the train to inform the equipment when to switch off and on.

Secondary Suspension Air Bag

Rubber air suspension bags are provided as the secondary suspension system for most modern trains. The air is supplied from the train’s compressed air system.

Wheel Slide Protection System Lead to Axlebox

Where a Wheel Slide Protection (WSP) system is fitted, axleboxes are fitted with speed sensors. These are connected by means of a cable attached to the WSP box cover on the axle end.

Shock Absorber (Damper)

To reduce the effects of vibration occurring as a result of the wheel/rail interface.

Axlebox Cover

Simple protection for the return current brush, if fitted, and the axle bearing lubrication.

Source: railway-technical.com