Major Plant and Machinery for Depot Area

A. Material Handling

| A.1. Overhead Travelling Crane Cranes are employed for lifting and lowering materials and moving materials in a rectangular area. |

| A.2. Jib Crane Jib crane enable lifting and lowering of a load within a fixed semi-circular area. |

| A.3. Pit Jack / Bogie Drop It is possible to remove the bogie, the wheelset and under coach components with dedicated interfaces. |

| A.4. Dummy Bogies They are used to move rail vehicles around the depot once they have been separated from their bogies. |

| A.5. Mobile Lifting Jacks They are designed to provide a flexible and reliable system for lifting all types of rolling stock for general maintenance requirements |

| A.6. Fork Lift Truck It is a powered industrial truck used to lift and move materials short distances. |

| A.7. Pallet Truck Pallet jacks are the most basic form of a forklift and are intended to move pallets within a warehouse. |

| A.8. Scissors Type Lifting Trolley These units help take the strain out of loading and unloading items from raised levels. |

B. Wheel shop

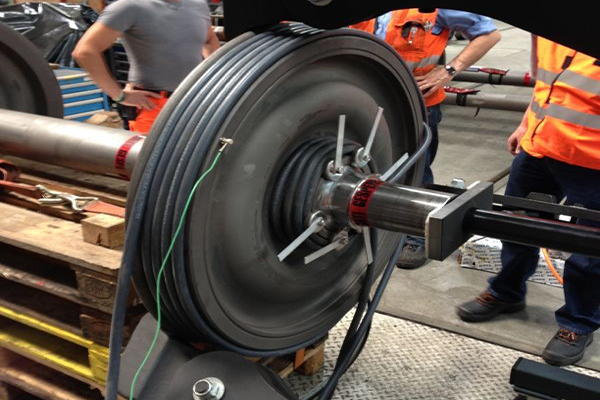

| B.1. Wheel Press Wheelset Presses are able to mount and dismount all of the elements on the axle (wheels, brake discs, gears and bearings). |

| B.2. Vertical boring (Turret Lathe) This machine is used to machine the hub/bore of the wheels. |

| B.3. Underfloor Wheel Lathe It is a specific machine tool for the corrective maintenance of railway rolling surfaces and train brake discs. |

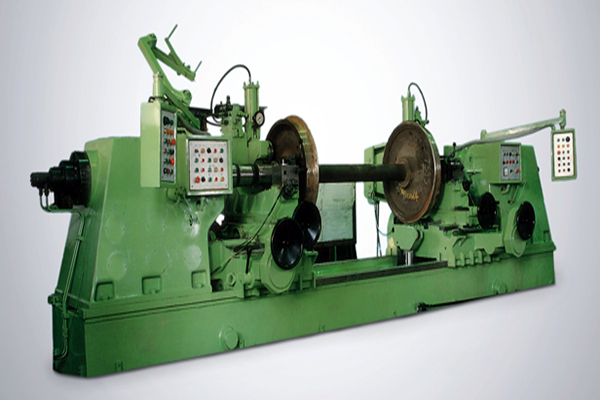

| B.4. Axle turning Lathe Machine performs finish turns the wheel seats, bearing journal fillets, and upset axle ends of an axle for new production as well as for reclaiming of axles. |

| B.5. Induction Heater Induction heater is used for mounting and demounting train wheel ring. |

| B.6. Bearing/Coupling Extractor It extract bearing and coupling of wheel for maintainance or overhaul. |

C. Bogie shop

| C.1. Bogie Wash/Cleaning Plant It is used for the washing of locomotive, tram and metro bogies as well as for the cleaning of loose pieces put on service trolleys. |

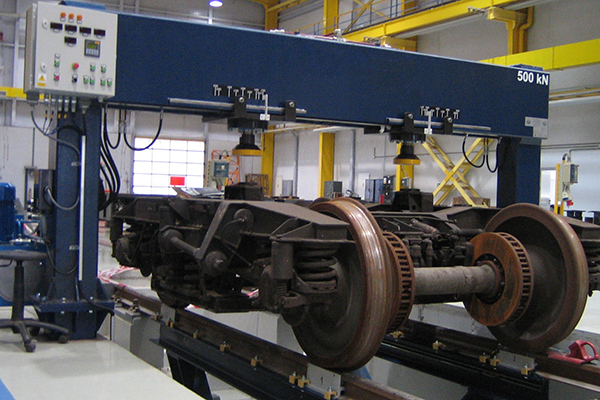

| C.2. Bogie Static Load Testing It simulates loading car body on bogie and inspects bogie technical parameters after assembling. |

| C.3. Shock Absorber Testing This bench performs testing of hydraulic shock absorbers in order to define performance, as well as tests with regard toughness. |

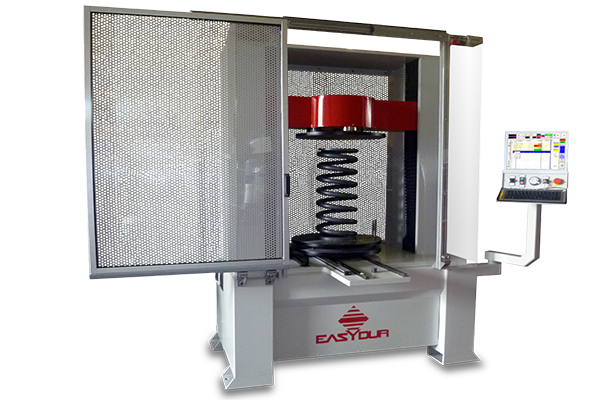

| C.4. Spring Scragging & Testing This instrument is for finding grinding defects on springs. |

| C.5. Magnaflex Crack Detector It is used for detecting surface cracks in steel and iron components with magnetic particle inspection method. |

D. Other M/CS

| D.1. Re‐railing Equipment It is for quick lifting, lateral displacement and returning to rail of derailed vehicles. |

| D.2. Portable Wheel Turning Lathe It can be used for elimination of some wheel defects, which appear while in service. |

| D.3. Automatic Washing Plant It wash the all exterior side of train by means of stationary automated washing equipment with modular unit. |

| D.4.Water De‐mineralizing Plant System provides treatment and reuse of wastewater after the train is washed. |

| D.5. Turn Table for One Car It is a rotating platform designed for use by a car. |

| D.6. Turntable for Bogies The turntable is an essential piece of equipment in any rail workshop and enables the easy movement of both wheelsets and bogies. |

| D.7. Driving Cab Simulator Simulators provide a real life train driving experience in an exact replica of their on-the-job environment. |

| D.8. Painting Booth Painting/heating/baking/drying process for separate parts is done in painting booths. |

Videos: